Fascia is used on a roof to give it extra protection from rainwater, insects, and other intruders. If you want to install some fascias by yourself, you can use a metal brake. Because you have to bend aluminum sheets to make a fascia. And it will help if you know how to use a metal brake for fascia.

This metal brake thing is a tool that is used to bend metal sheets at a desirable angle. You can bend thin metal sheets without using a brake. But it is easier to use a brake for the job. You can either buy a brake or rent it from a hardware store or places like that.

In any case, you should have the brake for a few days before you actually try to use it for fascia. Familiarize with the tool and do some practice bends. Then after you have figured out how it works get ready to prepare some fascia. Here is our guide on how to do it.

How to use a metal brake for fascia – step by step

Now let’s see how you can properly use a metal brake for your fascia.

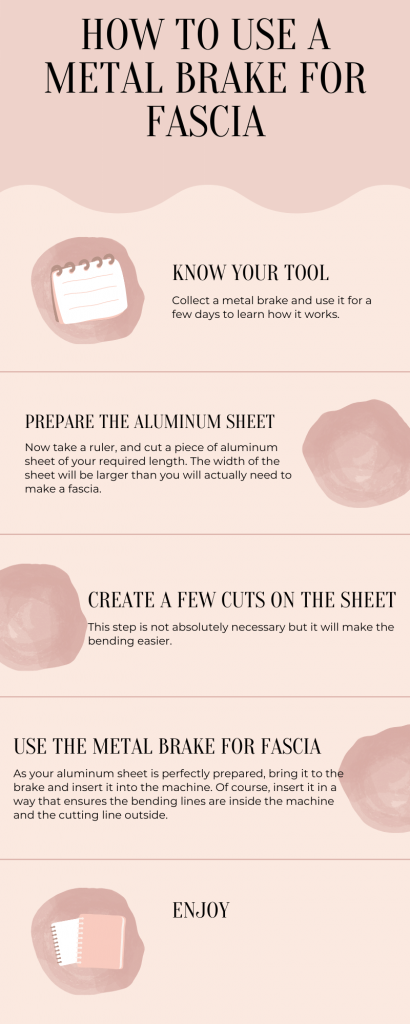

Step-1: Know your tool

This is really important. First, collect a metal brake either by buying or renting. Then use it for a few days to learn how it works. Practice bending on scrap metal before doing it on the actual aluminum sheets. This will make the bending a lot easier.

But make sure you pick the best siding brake

Once you figure out the most efficient way of getting the job done, it will save your time and energy. So, make a plan from start to end on exactly how you are going to handle the metal sheet and insert it in the brake, and so on.

Step-2: Prepare the aluminum sheet

After you have familiarized yourself with the metal brake and made your plan, the next step is to prepare the aluminum sheet. Now take a ruler, and cut a piece of aluminum sheet of your required length. The width of the sheet will be larger than you will actually need to make a fascia.

So, measure the width from the side that will enter the brake. Mark at three points that indicate 1 inch, 7 inches, and 8 inches width from that particular side. You will bend the sheet at the first two points and cut it. Mark the sheet on both ends perpendicular to the side that will go in horizontally.

Step-3: Create a few cuts on the sheet

This step is not absolutely necessary but it will make the bending easier. What you will need to do is create three lines joining the marking on both sides of the sheet. Two are bending lines at 1 inch and 7 inches and one is a cutting line at 8 inches. And at the cutting line create deep cuts all over the line. Because when you are going to bend the sheet along this line, it will easily then break. And on the two bending lines create random cuts, not so deep. You don’t want it to break along this line. You just want to make the bending a little easier.

Step-4: Use the metal brake for fascia

This is the final step and the step you were waiting for. As your aluminum sheet is perfectly prepared, bring it to the brake and insert it into the machine. Of course, insert it in a way that ensures the bending lines are inside the machine and the cutting line outside.

Now, first, work on the cutting line. Use the brake along that line and bend the sheet. And you will see the sheet will easily break along the line. Now move the excess sheet away. And this time work on the bending line at 7 inches width. Bend it all the way so that it touches the sheet on the inside.

The next step is to do the most important bending which is along the 1-inch line. Bring the sheet to the right position and start bending. You want a 90-degree bend at this point. So, bend a little more than 90 degrees as the sheet will show resistance and return back a little. If you have got a 90 degree bend your job is well done.

Conclusion

Now you know how to use a metal brake for fascia. So, if you were planning on preparing some aluminum fascia this should make your life a lot easier. No doubt you can bend aluminum fascia without a metal brake, but using it certainly is the easier and faster way to do it.

What you should keep in mind is, only go to the final step after you know the basics of a metal brake. When you feel comfortable using it only then use it for fascia. This will save both your time and energy. Make a detailed plan for the job beforehand. Good luck with your metal brake and fascia.